Course Summary

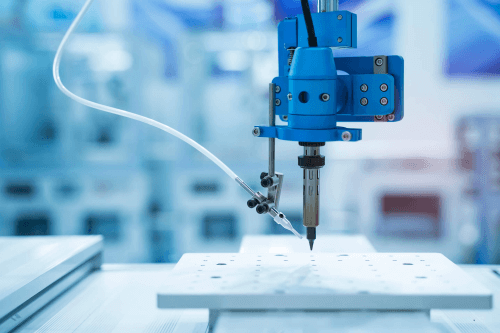

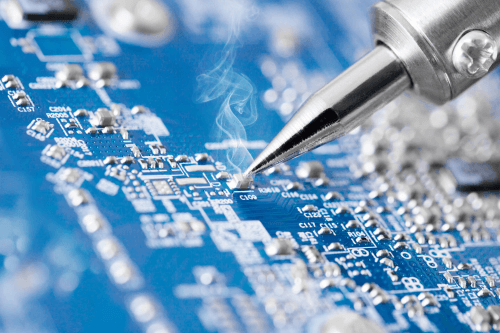

The AIM Traininig Production Line High Reliability Soldering Course is a “hands on” training course which will show the importance of correct soldering techniques to achieve the preferred high reliability solder joints.

The course length is usually a full day course however can be split into 2 x ½ day sessions for companies with larger groups. Each attendee is supplied with their own pcb with loose components to hand load from which they will be assessed and educated of additional techniques to improve their soldering ability. Throughout the day many topics will be covered which are listed below.

At the end of the course each attendee will receive their Certificate Of Completion.

These courses are conducted on customers premises or at AIM Training Centres. Minimum company group of 6 attendees required.

Topics Include

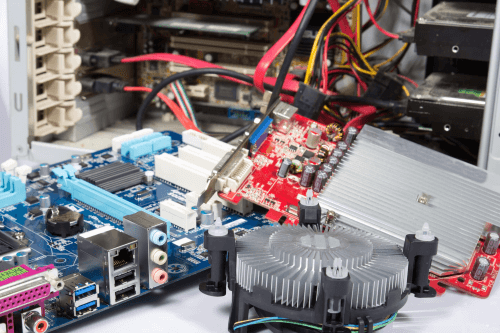

- Solder Compositions: What is the alloy composition of leaded and lead free solders and what are the differences of each.

- Mixing Solder Alloys: Why is it dangerous to mix leaded and lead free alloys?

- Visual Appearance: What visual differences are there between leaded and lead free solders?

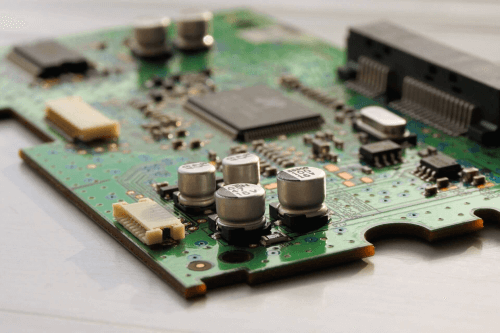

- Cleaning Process: Assessing students cleaning process and advising methods to improve process’s

- Soldering Temperatures: Soldering iron equipment training, temperature setup and correct tip selection.

- Equipment Maintenance: Maintenance education to equipment and maximize life of equipment and consumables

- The Sponge Debate: Sponges vs brass curls, what should you be using to ensure maximum tip life?

- Final Inspection: Inspection of solder joints and understanding of successful and unsuccessful reflow.