Course Summary

The IPC-A-610 is the most widely used specification published by the IPC for the electronics manufacturing industry.

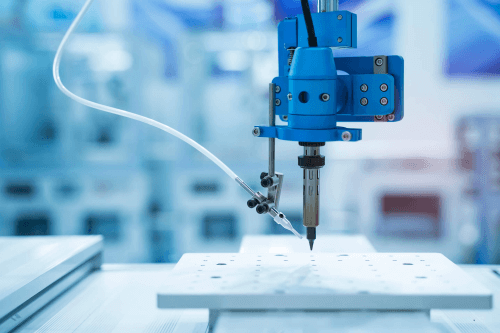

This course is designed to help electronic manufacturers achieve the highest quality, highest productivity, and most cost-effective production by ensuring their workers can correctly apply the acceptability criteria of IPC-A-610.

The education and training goal of this program is to improve individual discrimination skills, i.e., to improve accuracy of discrimination between an ‘acceptable’ or ‘non-conforming’ electronic assembly per the IPC-A-610 series.

This program will also teach individuals the reasons for the accept/reject criteria to enhance their motivation and ability to consistently and correctly apply the discrimination criteria.

Throughout this three-day course, employees will be trained to correctly apply the accept/non-conforming criteria for the applicable class of production: Consumer Products (Class 1), General Industrial (Class 2), and High Reliability (Class 3).

Included Modules

AFTER COMPLETION: Students receive an IPC-A-610 Certified IPC Specialist (CIS) Certificate* with an overall score of 70% or better on both the Open Book and Closed Book end-of-course test components. Certification is valid for up to two (2) years.

Module 1 (Required)

Introduction: IPC Professional Policies and Procedures

Module 2 (Required)

Foreword, Applicable Documents, and Handling

Module 3 (Required)

Hardware Installation

Module 4 (Optional)

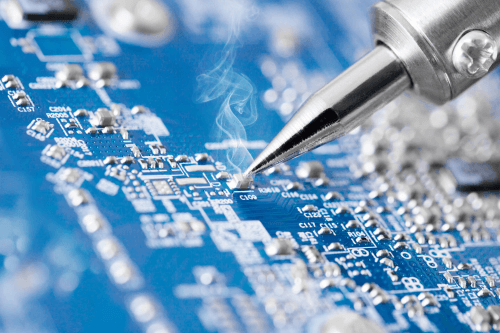

Soldering, including High Voltage

Module 5* (Optional)

Terminal Connections

Module 6* (Optional)

Through Hole Technology, including TH Jumper Wires

Module 7* (Optional)

Surface Mount Assemblies, including SMT Jumper Wires

Module 8 (Optional)

Component Damage and Printed Circuit Boards and Assemblies

Module 9 (Optional)

Solderless Wire Wrap

Course Summary/Review (Required)

- Open Book Examination

- Closed Book Examination

- Review of Test Results

*Modules 5, 6, and 7 require the completion of Modules 4 & 8 first.

Handbook

The IPC-A-610 Acceptability of Electronic Assemblies handbook is the most widely used specification published by the IPC for the electronics manufacturing industry.

This publication is a visual document that provides comprehensive accept/reject criteria for the handling of electronic assemblies, mechanical assemblies, component installation, location/orientation, soldering, and cleanliness of assemblies, marking of assemblies, coatings, laminate conditions, discrete wiring assembly and surface mount assemblies.

Topics include:

- Terms and Definitions

- Handling Electronic Assemblies

- Mechanical Assemblies

- Component Installation Location/Orientation

- Soldering

- Cleanliness

- Marking and Coatings

- Laminate Conditions

- Discrete Wiring Assembly

- Surface Mount Assemblies