Course Summary

The IPC/WHMA-A-620 is the first industry consensus standard for cable and wire harness fabrication and installation.

The Operator program is modularised to allow for maximum flexibility to meet individual needs. This training will familiarize the student with the general requirements of the IPC/WHMA-A-620, and will conclude with a qualifying examination.

The IPC/WHMA-A-620 is modelled after the IPC-A-610: IPC’s most widely used standard with an international reputation as THE source for product acceptance criteria for consumer and high reliability printed circuit assemblies.

Throughout the course, students will be trained to reference the IPC/WHMA-A-620 standard to make acceptable/reject decisions, interpret terminology and their definitions, and successfully pass the written exam with a score of 70% or better

Topics Include

Candidates take an open book exam after each module. An individual score of 70% or better on each exam is required. Candidates who pass the course modules receive an IPC Certificate of Proficiency indicating the areas of the IPC/WHMA-A-620 that were taught.

AFTER COMPLETION: Candidates are certified for up to two (2) years, after which time they will need to attend a re-certification course to maintain their certification.

Module 1 (Required)

- Introduction: IPC Professional Policies and Procedures (Section 1)

- Foreword and Applicable Documents (Section 2)

- Cable/Wire Preparation (Section 3)

- Measuring Cable Assemblies (Section 11)

- Testing Cable Assemblies (Section 19)

Module 2 (Optional)

- Crimp Terminations (Section 5)

- Insulation Displacement Connections (Section 6)

Module 3 (Optional)

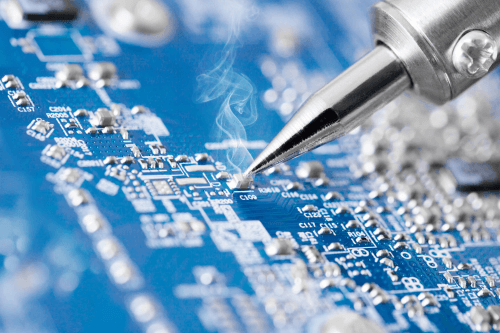

- Soldered Terminations (Section 4)

Module 4 (Optional)

- Connectorisation (Section 9)

- Molding/Potting (Section 10)

Module 5 (Optional)

- Splices (Section 8)

Module 6 (Optional)

- Marking/Labeling (Section 12)

- Wire Bundle Securing (Section 14)

- Shielding (Section 15)

- Protective Coverings (Section 16)

Module 7 (Optional)

- Coaxial and Twinaxial Cable Assemblies (Section 13)

Module 8 (Optional)

- Solderless Wire Wrap (Section 18)

Note: An ADDITIONAL 1 Day Practical module also available. *Click here to enquire*

Handbook

The latest revision of the only industry-consensus standard for Requirements and Acceptance of Cable and Wire Harness Assemblies includes new sections for safety wiring, safety cable, grommets, and raceways, along with updated information across many of the sections.

With 422 pages and over 700 photographs and illustrations, this standard describes materials, methods, tests and acceptance criteria for producing crimped, mechanically secured and soldered interconnections and the related assembly activities associated with cable and harness assemblies.