Course Summary

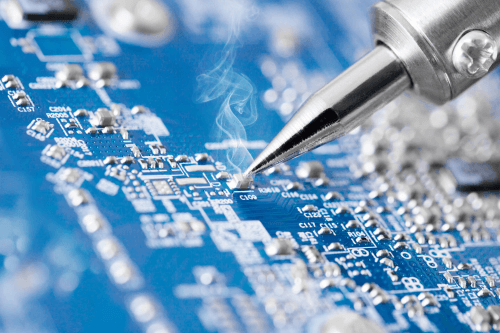

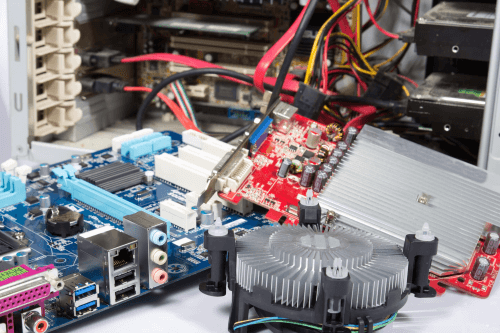

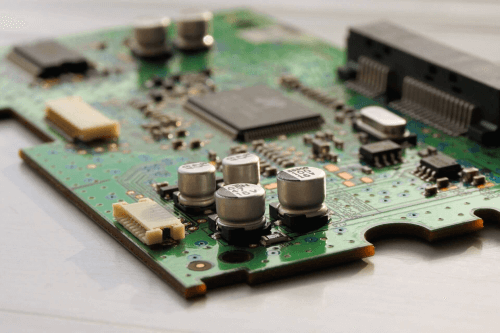

This course focuses on rework and repair for electronic assemblies, substrates, mechanical assemblies, component removal and placement and PCB modifications.

This course is performed to many of the major warranty service centers across Australia, military and aviation workshops and is now available for companies or individuals looking advance their existing skills to tackle fine pitch surface mount rework or heavy through hole applications.

The course length is usually a full day course. Each attendee is supplied with their own PCB with loose through hole and surface mount components to hand load from which they will be assessed and educated of additional techniques to improve their soldering ability.

A theory based introduction to PCB circuit and laminate repair is covered in this course. If you wish for this module to be hands on, a 2nd or 3rd day’s training is required.

At the end of the course each attendee will receive their Certificate of Completion for the Advanced Rework Course.

These courses are conducted on customers premises or at AIM Training Centres. Minimum company group of 6 attendees required.

Topics Include

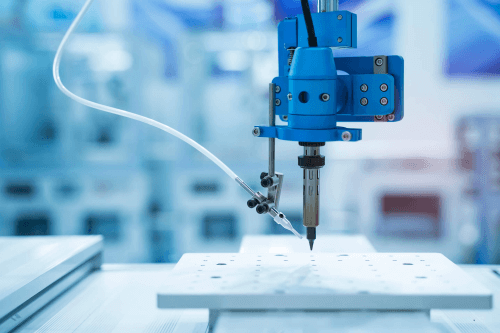

- Fine pitch surface mount placement and removal using soldering equipment.

- Fine pitch surface mount placement and removal using hot air or infrared equipment

- Through hole component removal using continuous de-soldering systems

- Improving techniques using essential consumables i.e. solder pastes, flux gels etc

- Education on which solders, fluxes are the best to use for your application

- Cleaning techniques to remove the no clean white flux residue

- Soldering equipment education

- Working with lead free solders and improving your techniques

- Soldering equipment maintenance