Course Summary

The IPC- J-STD-001 training course has become the industry authority for electronics assembly manufacturing.

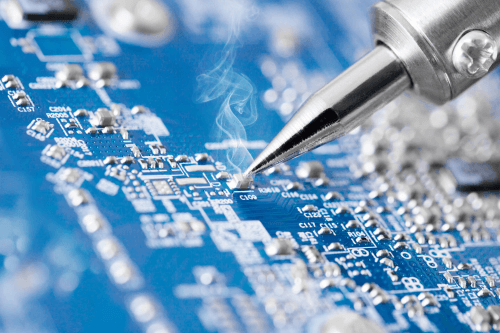

The standard describes materials, methods, and verification criteria for producing high quality soldered inter-connections. It emphasizes process control, as well as setting industry consensus requirements for a broad range of electronic products.

In this course, you select the modules/topics that meet your training requirements.

The IPC- J-STD-001 Operator Proficiency Series is a comprehensive, knowledge-based series of modules that certify students to the methods and procedures presented in the J-STD-001 document. Designed for operators, the program helps workers to interpret the J-STD-001 specification through lecture, demonstration, and labs.

Included Modules

AFTER COMPLETION: Certification requires a 70% or better grade for each module completed. Operators will be certified for up to two (2) years.

Module 1 – Overview of J-STD-001 (Required)

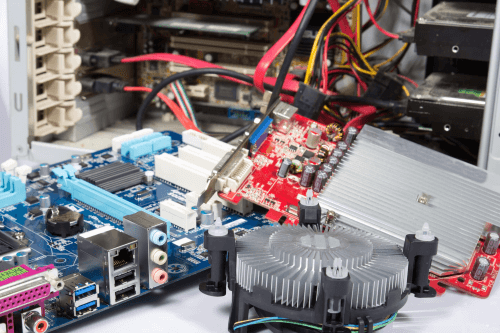

- Safety, EOS/ESD, Classes of Equipment

- Solder Theory of Solderability

- Solder Flux and Solder Alloys

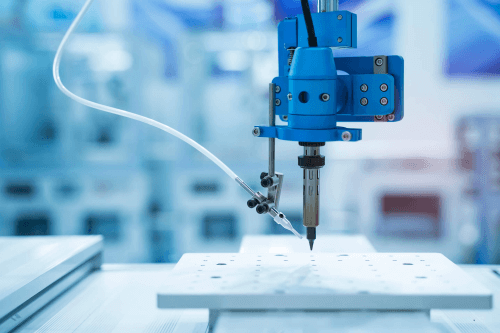

- Facilities, Tools & Equipment

- PTH-Assembly/Solder

- Surface Mount Technology

- Cleaning

Module 2 – Wires and Terminals (Optional)

- Wire Preparation and Solder to Terminals

- Terminal Inspection

- Wire and Terminal Demo and Lab

Module 3 – Through-Hole (Optional)

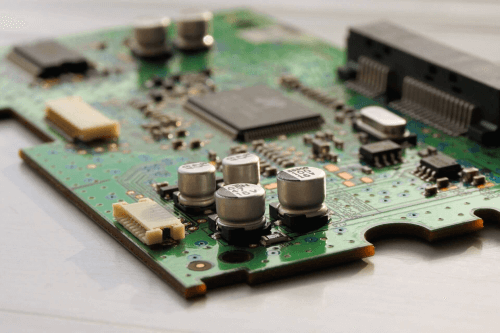

- Preparation and Component Mounting

- PTH Inspection Criteria

- PTH Soldering Demo and Lab

Module 4 – Surface Mount (Optional)

- SMT Criteria

- SMT Demo and Lab

Module 5 – Inspection Methods (Optional)

- Theory of Inspection

- SPC Defect Definition and Disposition

- Inspection Skills Demo and Lab